IoT in Manufacturing | Use-Cases, Benefits and Challenges

Also, With the Internet of Things (IoT app development), people can access the Internet and digital networks by using smartphones and computers. They can share information and have conversations, purchase products, and more. IoT has broken the barriers by connecting different technologies and placing them under one roof. It is a revolutionary technology that can simplify processes and reduce costs as well.

From data-driven insights to automation, the Internet of Things can boost existing resources and increase the efficiency of workers. With these encouraging figures, using IoT services in the manufacturing industry as well as business is an excellent way to achieve digital transformation. In this article, we’ll explore most of the use cases, benefits, and major challenges of IoT in manufacturing. You will also learn how an IoT App Development Company can help you make your investment in IoT much worthy.

IoT in the Manufacturing: Top Use-Cases

# Remote Production Control

Internet of Things lets you monitor the manufacturing process in real-time. It is not just about the state of machinery and safety of factories, but also the security of the factory. For instance, by installing IoT-powered cameras mounted on building roofs, or at the doors of factories, you can detect various alarm signals (smoke or fire, violence, etc.) and notify security agencies.

Furthermore, you can hire IoT app developers and make control rooms completely automated by using IoT devices. These can be smart buttons or video recorders that have alarm capabilities. In this way, managers get news about any suspicious activity such as productivity declines, unauthorized access, etc. This reduces risk and increases overall productivity metrics.

On top of that, it helps in monitoring employee hours of attendance, shift schedules, and working hours. In this way, managers can increase employee retention, increase employee productivity, or even eliminate the expense of labor.

# Asset Tracking and Condition Monitoring

Asset tracking is an additional aspect of manufacturing that could be improved by the integration of IoT app development technologies. It’s a way of monitoring the state of the tools, equipment, materials, and other assets to reduce the risk of losing them.

IoT-powered tires have sensors that offer real-time information about their use that can assist managers schedule maintenance activities more effectively. Also, it permits the identification of the application for proper management.

# Logistics Management

You can extend asset tracking to other assets that are non-material. Internet of Things sensors can monitor a range of variables, including temperatures, humidity, and pressure. So, your company can track the energy consumption or waste produced by every asset. Just hire IoT app developers and your company can use the technology to improve logistics operations and increase efficiency in their delivery procedures.

In manufacturing, it assists in reducing losses that happen due to spoilage of materials and products and decreases the transportation cost and response time. IoT app development-led logistics data can be used to anticipate future issues during the manufacturing process (e.g. the deficiency of electricity in certain seasons).

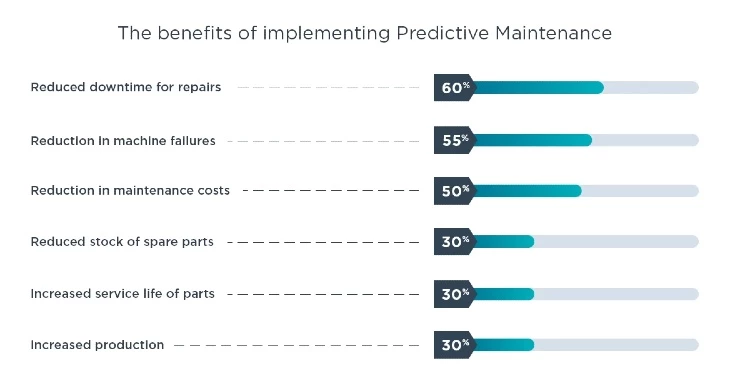

# Predictive Repairing

It is among the most promising fields since it uses IoT-powered devices that collect data about the condition and the position of the components. Manufacturers are instantly informed about needed maintenance or replacements if an important parameter is identified. This allows manufacturers to lower their costs and achieve a higher level of satisfaction for customers as they get good-quality products.

Benefits of IoT in Manufacturing

Below are a few of the advantages of IoT app development in manufacturing:

1. 24-hour Monitoring and Quality Control

Including production equipment with sensors measures their operational time by keeping labor force, and other variables into mind. This allows manufacturers to continuously check their production and get aware of whether there is a delay in production. And automation of production using robots or other similar technology could ensure that each product meets requirements for quality.

2. Production Efficiency

Utilizing sensors to control quality and inventory management and other tasks that consume time will allow the workforce to work on more challenging tasks. Additionally, IoT app development would leverage data from the sensors, devices, and monitors to keep track of KPIs, such as worker absences and vehicle accidents. It also will help to prevent any other damages that could affect normal operations. These will all lead to better production efficiency.

3. Shipment and Asset Tracking

IoT app development technology permits the tracking of shipments and assets. You can monitor supply chain assets, such as raw materials continuously. It will allow supervisors to determine what time the following batch of items must be sent out prior to the next shipment of raw materials arriving.

4. Safer Workplace

You can distribute sensors all over the manufacturing plant. They monitor the surrounding environment by monitoring the quality of the air emission levels, hygiene, and air quality. Alarm systems can be installed to make use of facial recognition to detect and sound a ring whenever the worker isn’t wearing the proper helmet. You can contact an IoT App Development Company and discuss this crucial aspect to use this technology.

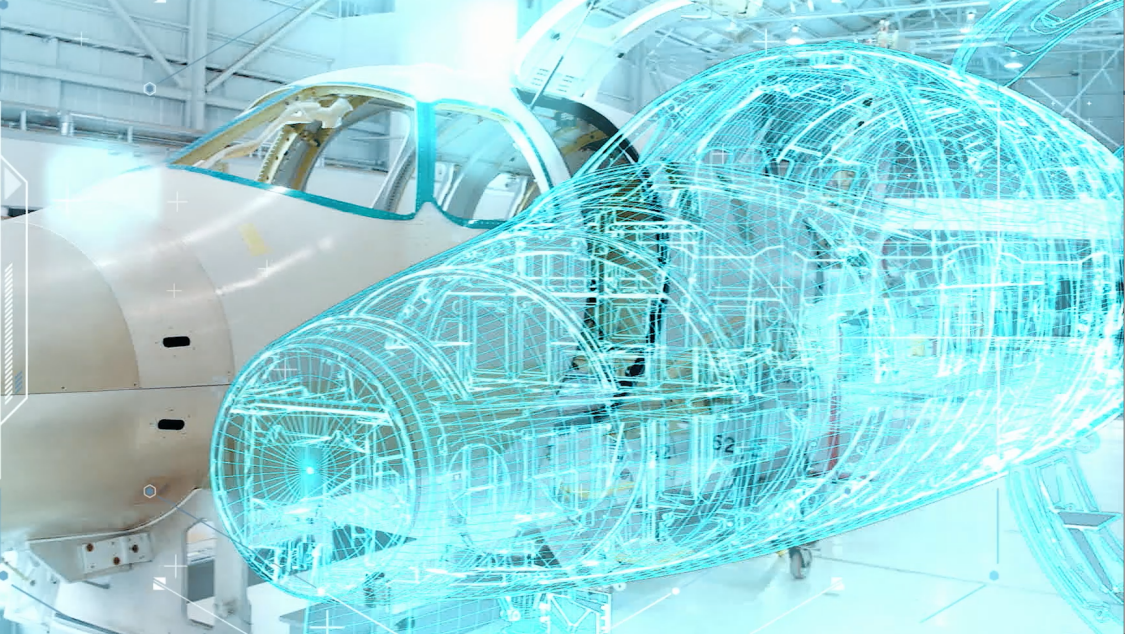

5. Digital Twins

Manufacturing companies can create digital twins based on data collected via IoT devices. Digital twins can help manufacturers estimate the life of their equipment or test the effectiveness of supply chain arrangements in a virtual setting. Simply hire IoT app developers and get started today to save cost.

6- Smart Metering System

An IoT ecosystem can add smart meters which keep a complete record of the consumption of water, power consumption, and even fuels. This allows companies to thoroughly review their power usage, consumption inefficiencies, and their carbon footprint. In turn, this increases efficiency and ensures the requirements of regulatory and governmental compliance.

Challenges to IoT in Manufacturing

Using IoT devices to their full potential needs great planning and assessment. If you are setting up an IoT app development project, think about the following.

Challenge 1 – Interoperability

Manufacturers encounter an increasing amount of interoperability problems when integrating their devices into different systems and IT infrastructures. This is because of the absence of standardization among IoT devices and any IoT Development Company. The lack of guidelines on interfacing and interacting with devices from other manufacturers is a major issue for companies who wish to incorporate Internet of Things in operations.

Challenge 2 – Data Privacy

Manufacturers face a number of challenges while collecting data from embedded sensors. When connecting these devices to the Internet manufacturers are also exposing themselves to cyberattacks. Internet of Things-based manufacturing requires a complete plan for protecting data at the beginning of the project to ensure that the project meets the security standards and the reduction of privacy security risks.

In response to these issues, manufacturers are gradually increasing their knowledge of the ways they can use IoT app development technology. There is a lot to be done until this technology is considered mature but still IoT-based solutions have already been used in a variety of sectors.

Challenge 3 – Security

Well, the Internet of Things offers new attack options that create additional vulnerabilities that hackers may take advantage of. Security risks can arise in all phases of IoT-driven manufacturing, from acquiring and processing data to directing the machinery remotely. A study found that over 60% of businesses that use the Internet of Technology technologies experience security risks.

The risk of not taking these challenges seriously has more dangers than just financial risks. In order to solve these problems, it requires conducting an assessment of cybersecurity risks regularly throughout the IIoT devices. When you enlighten yourself with the technology and risks, you can avoid most of the problems easily. Then you just have to partner with an IoT App Development Company and get started with your project.

Some Last Words

IoT is an essential element of the future technology landscape. It is already making its way into every sector you can imagine including manufacturing. But, in order to successfully integrate IoT technologies in your business processes, you should be aware of the specific issues that manufacturers are encountering presently. Like any major technological change, there is a time frame for the concept to develop. This is why patience is necessary for investing in IoT.

You can hire IoT app developers from a reputable IoT App Development Company like MobileCoderz for better outcomes. We have IoT app developers who offer services ranging from concept growth to final IoT app development services. We develop custom IoT applications that are built the way our customers want. As a trusted IoT application development partner, we take security extremely seriously and work by keeping our clients’ requirements in mind.

-

Developing Mobile Applications for the Internet of Things (IoT): Opportunities and Considerations

Developing Mobile Applications for the Internet of Things (IoT): Opportunities and Considerations -

The Complete Guide to Digital Wallet App Development in 2023

The Complete Guide to Digital Wallet App Development in 2023 -

Top 8 Innovative FinTech App Ideas for Startups in 2023

Top 8 Innovative FinTech App Ideas for Startups in 2023